How to make a jack plane

Practical Action

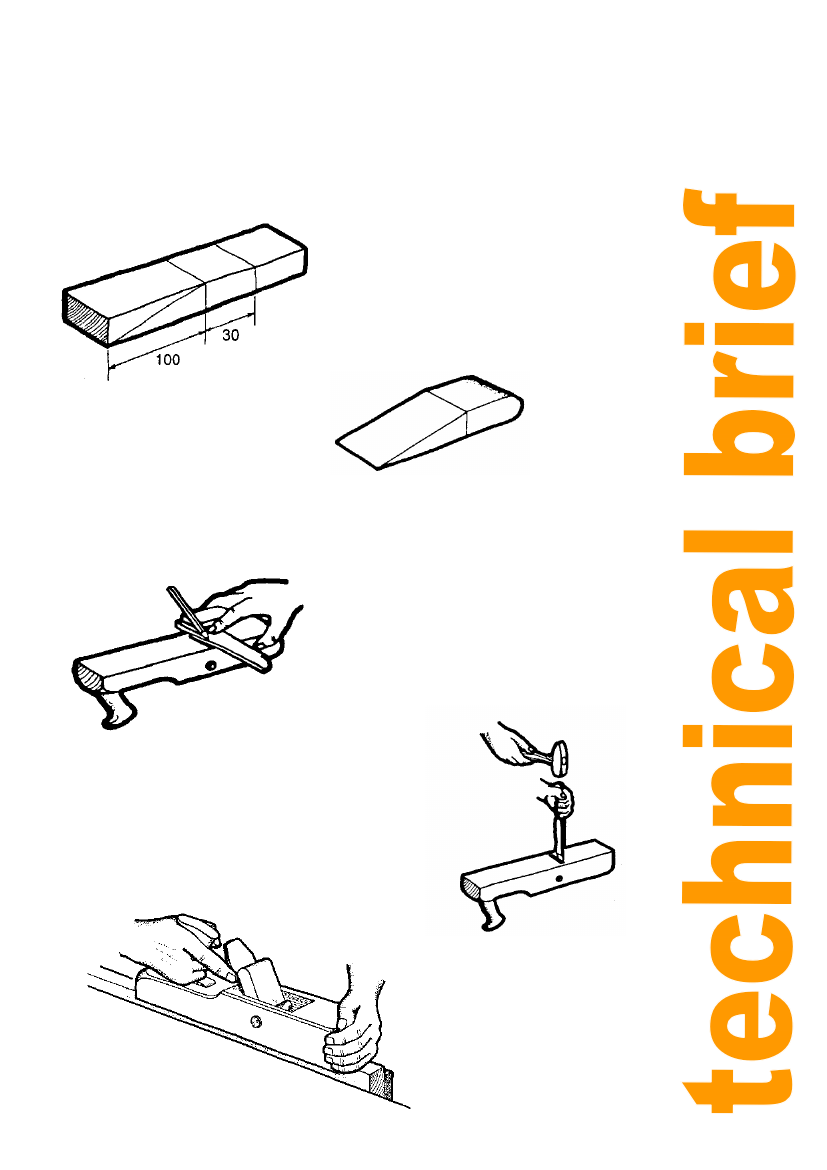

Making the wedge

Take the 200mm x 50mm x 20mm piece prepared for the wedge. Square a line all round

100mm from one end, and mark the angle for the wedge. Square another line 130mm from

the same end to mark the top of the wedge.

Clamp the wedge vertically in the vice and use a

ripsaw to cut the angle. Plane the sawn face by

clamping it in a vice horizontally, with a small

piece of timber to support the thin end.

Saw off the top of the wedge with a tenon-saw

and round it off with a chisel and sandpaper to

prevent it splitting when struck with a hammer.

The finished wedge should look like this.

Fitting the blade

Before the plane can be used the blade will have to be fitted. If you have bought a blade from

a hardware shop it should fit easily through the mouth. If the blade you are going to use has

been made by a blacksmith it may be too thick. The mouth will have to be opened out to

allow it to extend below the sole of the plane.

Square a line on the sole, 2mm from the front of

the mouth. Use a wide chisel to pare straight

down into the front of the throat. Repeat this

process until there is a gap of about 3mm or

4mm between the cutting edge and the front of

the mouth.

Position the blade so that the cutting edge is about 5mm

inside the throat and wedge it tight.

Finally, clamp the plane upside down in a vice (without

the blade in place) and plane the sole straight and true.

The plane is now ready to use.

9